ELECTRIC CHAIN HOISTS

LK ELECTRIC CHAIN HOISTS STANDARD FEATURES:

- 1/8 to 5 ton capacities (125 kg – 5000 kg) / Single fall up to 2.5 ton (2,500 kg), two fall up to 5 tons (5000 kg)

- 10, 15 and 20 ft. (3, 4.5 and 6 m) lifts standard; additional lifting heights available up to 98 ft. (30 m) single fall, 49 ft. (15 m) two fall

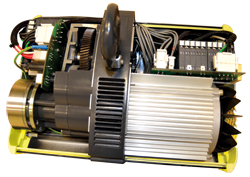

- Two-speed TMU trolley drive unit (trolley speed is 80/20 FPM)

- Trolley brake, drop lugs and bumpers are standard

- Variable frequency drive option on TMU

- Various hoist suspensions including hook, push trolley & motorized trolley (TMU)

- Disc brake positioned after the mechanical overload device (clutch); on the load path

- High density polyethylene black chain container

- Two or three step helical gear

VARIABLE SPEED HOISTS

LK Variable speed electric chain hoists enable commercial and industrial facilities to reduce both energy consumption and maintenance costs, while offering flexible speed control of the load (lifting and traveling). Smooth hoist starts and stops reduce the wear and mechanical stresses on structures and minimizes the load sway. All at an affordable price

STANDARD HOIST FEATURES INCLUDE

- Load capacities from 1/4 to 2 ton

- Hook suspended models, push trolley and motorized trolley model

- Trolley brake and bumper are standard with motorized trolley

- Stepless speed control for hoist body is constructed of pressure-cast aluminum for light-weight and easy handling, epoxy paint for corrosion resistance and ribbed for better heat dissipation

- All hoist models are equipped with a torque-limiting device for hoist overload protection

- Upper and lower limit switches

- The friction-type torque limiter is integrated with the brake to insure that the load is always stopped when the control button is released

- Hoist motor thermal protection

- Chain container

- Plug-in push button pendant with E-stop for quick replacement

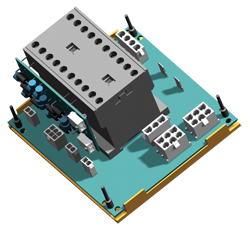

CONTROLMASTER INVERTER TECHNOLOGY INCLUDES

The LK variable speed hoist motion is based on a

LK10 frame with a ControlMaster inverter.

The ControlMaster™ inverter offers built-in flexibility such as speed control types (stepless, multi-step), selection of output speeds, over-current protection, and a removable key pad with a LED display.

Includes the following:

- ControlMaster inverter

- Brake resistance

- Brake control relay and rectifier

- Sensor bearing and speed protection – System Includes:

- Stall protection: stops the motion if the motor does not rotate. Overspeed protection: stops the motion if the speed of the motor is 20% above nominal speed.

OPTIONAL FEATURES INCLUDE

- Motorized trolley motor thermal protection

- Special patented track, swiveling motor driven, and low headroom trolley configurations

- Upper and lower geared limit switch

- Stainless steel chain hook and block

- Outdoor weather protection options

- Radio remote control

- Hour counter

- Works with R&M bridge crane kits

Food Grade Hoist Options

Stainless steel load chain, stainless steel lower hooks, stainless steel bottom block, and food grade lubricant can be provided for food handling and pharmaceutical hoist applications.

HOIST INVERTER

Inverter Variable (EP) Speed Control

Infinitely variable (EP) speed control is stepless and gives the user control to accelerate and hold any speed from the minimum speed to the maximum speed.

Multi-step (MS) Speed Control

Multi-step speed control (MS) gives the user two distinct and programmable operating speeds.

Automation (AU) Control

Automation control (AU) allows the use of any control device with an output in the range of 0 – 10V (radio controls, computer, PLC).

Digichain controls are ergonomically designed handle control allowing LK hoists to be used as an extension of the operator’s arm. Ergonomic control designed specifically for one-handed operation.

Available on LK01 and LK05 model hoists

- 1/8 to 1/2 ton capacities

- Single fall only

- Standard E-stop button

- NEMA type 3R (IP-55) protection rating

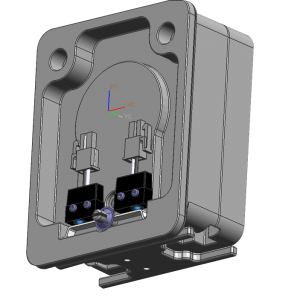

LK INNOVATIVE SLIP CLUTCH & BRAKE:

- DC brake for quite operation; IP66 protection class

- Easy to adjust slip clutch/overload device

- Hoist brake designed to last for the DWP (designed working period) of the hoist. No air gap adjustment required

- Disc brake is positioned after the clutch on load path

- Design enables brake to hold load without interaction of the clutch

LK ELECTRICAL LIMIT SWITCH:

- Rocker style electrical limit, protected inside hoist body

- Limit switch triggered by rubber protection of bottom block or rubber cased fall stop on loose end

- Mounted to pressure cast aluminum chain guide

LK LOAD WHEEL:

- Precision manufactured, hardened load wheel

- Patented load wheel with five intermediate teeth; low noise, less chain wear, for smooth and quiet operation

LK HIGH PERFORMANCE TEFC (TOTALLY ENCLOSED FAN COOLED) MOTOR:

- Heavy duty type 50% ED rating (exceeds 30 min. rating) on three phase motors

- IP55 protection; Class F Insulation

- Optimum cooling with ribbed aluminum construction motor for maximum surface area

- Motor thermal protection with bi-metal switch