Harrington Spreader Beams come in a wide variety of styles, capabilities and capacities. From a standard duty spreader beams to box spreader beams, Harrington offers versatility paired with Made in the USA quality.

SEE THE COMPLETE LINE OF HARRINGTON LIFTING BEAMS, CLICK HERE FOR MORE INFORMATION

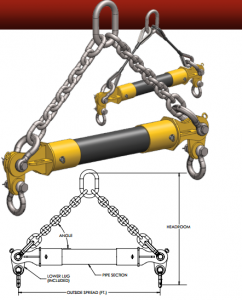

HSDSB STANDARD DUTY SPREADER BEAM

FEATURES

- This style of lifter is utilized with upper rigging spread between two lift points that adds extra stability to the lift.

- This spreader beam should be utilized where headroom is not limited and comes standard with a pair of swivel hooks.

- Can be supplied with optional chain or wire rope top rigging.

- Harrington Spreader Beams are engineered and manufactured to ASME B30.20 & BTH-1 Design Category B Service Class 2.

- 100% of ALL spreader beams are Proof-Tested to 125% capacity and certificates supplied at No Additional Charge.

- Made in USA.

OPTIONS

- Higher capacities

- Additional lengths

- Upper and lower shackle design

- Chain top rigging

- Wire rope top rigging

HATSB ADJUSTABLE TELESCOPIC SPREADER BEAM

FEATURES

- This style of spreader beam is telescopic to accommodate various load sizes – 2 through 15 ton capacities, adjustable increments at 1” and 20 through 40 ton capacities, adjustable increments at 12”.

- This style of lifter is utilized with upper rigging spread between two lift points that adds extra stability to the lift.

- This spreader beam should be utilized where headroom is not limited and comes standard with a pair of swivel hooks.

- Can be supplied with optional chain or wire rope top rigging.

- Harrington Spreader Beams are engineered and manufactured to ASME B30.20 & BTH-1 Design Category B Service Class 2.

- 100% of ALL spreader beams are ProofTested to 125% capacity and certificates supplied at No Additional Charge.

- Made in USA.

OPTIONS

- Higher capacities

- Additional lengths

- Upper and lower shackle design

- Chain top rigging

- Wire rope top rigging

HBXSB BOX SPREADER BEAM

FEATURES

- This style of spreader beam is designed to lift large bulky loads and can be rigged to handle objects with an offset center of gravity.

- Designed to meet your specific lifting requirements and can be manufactured in a welded or bolt together design.

- Product shown is as a bolt-together style with special corner assemblies whereby the shackle lugs can rotate into position in order to prevent side loading.

- If adjustability is required, this style of box spreader beam can be designed with telescopic lengths and/or widths to accommodate various load sizes.

- This spreader beam should be utilized where headroom is not limited.

- This style of lifter is utilized with upper rigging spread between four lift points that adds extra stability to the lift.

- Can be supplied with chain or wire rope top rigging.

- Harrington Spreader Beams are engineered and manufactured to ASME B30.20 & BTH-1 Design Category B Service Class 2.

- 100% of ALL spreader beams are Proof-Tested to 125% capacity and certificates supplied at No Additional Charge.

- Made in USA.

OPTIONS

- Swivel hooks

- Shackles

- Chain slings

- Other special lifting attachments

- Chain top rigging

- Wire rope top rigging

HECSB END CAP SPREADER BEAM

FEATURES

- This style of lifter is utilized with upper rigging spread between two lift points that adds extra stability to the lift.

- This spreader beam should be utilized where headroom is not limited and comes standard with upper and lower shackles.

- Standard pivoting lifting lugs provide the flexibility of a 75° to 90° lower rigging angle.

- Can be supplied with optional chain or wire rope top rigging.

- Harrington Spreader Beams are engineered and manufactured in accordance to ASME B30.20 & BTH-1 Design Category B Service Class 2.

- 100% of ALL end cap spreader beams are ProofTested to 125% capacity and certificates supplied at No Additional Charge.

- Made in USA.

OPTIONS

- Higher capacities

- Additional lengths

- Chain top rigging

- Wire rope top rigging

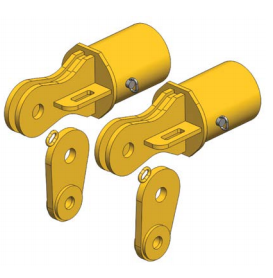

HEC END CAP HECP END CAP PIPE

FEATURES

- This style of lifting component supplied in pairs allows the user to assemble their own spreader beam by incorporating A53 Grade B, schedule 80 pipe along with upper and lower rigging.

- This style of spreader beam when assembled adds extra stability to the lift.

- This style of spreader beam when assembled should be utilized where headroomis not limited.

- Standard pivoting lifting lugs provide the flexibility of a 75° to 90° lower rigging angle.

- Includes standard assembly pins used to attach the End Cap to the A53 Grade B, schedule 80 pipe.

- Can be supplied with optional upper and lower shackles.

- Can be supplied with optional chain or wire rope top rigging.

- Harrington Spreader Beams are engineered and manufactured in accordance to ASME B30.20 & BTH-1 Design Category B Service Class 2 and complies when assembled per factory specifications.

- 100% of ALL end caps are Proof-Tested to 125% capacity and certificates supplied at No Additional Charge.

- Made in USA. FEATURES

OPTIONS

- Higher capacities

- Upper and lower shackles

- Chain top rigging

- Wire rope top rigging

HECP END CAP PIPE

FEATURES

- This style of lifting component supplied in pairs allows the user to assemble their own spreader beam by incorporating A53 Grade B, schedule 80 pipe along with upper and lower rigging.

- This style of spreader beam when assembled adds extra stability to the lift.

- This style of spreader beam when assembled should be utilized where headroomis not limited.

- Standard pivoting lifting lugs provide the flexibility of a 75° to 90° lower rigging angle.

- Includes standard assembly pins used to attach the End Cap to the A53 Grade B, schedule 80 pipe.

- Can be supplied with optional upper and lower shackles.

- Can be supplied with optional chain or wire rope top rigging.

- Harrington Spreader Beams are engineered and manufactured in accordance to ASME B30.20 & BTH-1 Design Category B Service Class 2 and complies when assembled per factory specifications.

- 100% of ALL end caps are Proof-Tested to 125% capacity and certificates supplied at No Additional Charge.

OPTIONS

- Higher capacities

- Upper and lower shackles

- Chain top rigging

- Wire rope top rigging