Lower and raise stage backdrops, curtains, lighting truss, projections screens, house lights, etc. at the touch of a button.

PERFECT FOR:

- over-stage

- front-of-house

- height-restricted spaces

- retrofitted spaces

- architecturally sensitive spaces

Contact SMI for all your theater rigging needs.

SAFER

Personnel stay on the ground while scenery, lighting gear, curtains and screens are raised and lowered via smart controls which meet or exceed industry standards.

GREATER FLEXIBILITY

ETC Rigging™ — with the smartest controls and automated hoists available, facilitates quick, affordable and safe solutions to varied, innovative productions, offering the kind of flexibility typically associated with an extensive and expensive architecture of catwalks.

Prodigy Hoists are able to transform sensitive, existing environments – whether a house of worship or a performance space in a re-purposed building – discreetly adding modern rigging capabilities, flexbilty, convenience and safety otherwise unachieveable.

SAVINGS FOR NEW CONSTRUCTION or RENOVATION

In addition to enhanced safety and lower operation costs, ETC Rigging offers significant upfront costs savings for both new construction and renovation projects.

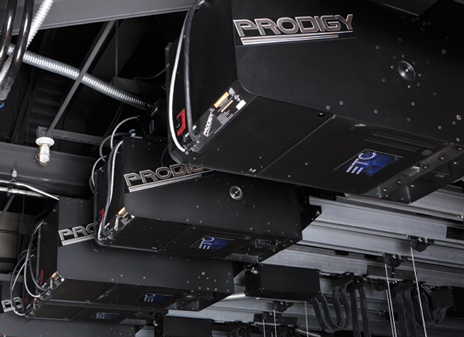

Prodigy Hoists:

If you thought that the safety, convenience and flexibility of an automated hoist system was out of reach because of the size of your budget or your venue, think again. The Prodigy® family hoist systems bring you the performance, at a price that defies its high lifting capacities.

Features

Core features from the Prodigy® family hoist systems, such as eight 3/16” lift lines, 50 feet of travel, load cell, slack line detection, positioning encoder, and the option to use our revolutionary compression tube technology or traditional rigging styles.

Prodigy Powerhead

Lighter than other automated systems and 1/3 of the length. The Powerhead ships compactly with pre-assembled slide-out loft blocks and pre-strung cables for easy, time-saving installation.

Every hoist tested under full load before leaving the factory

ETC wants the user-experience to be the best possible – from the moment the system is turned on. Every Prodigy hoist is tested under full load before it leaves the factory. All electrical and electronic connections, lift-line integrity and terminations, limit-switch functions, operation switches, and other components are tested by ETC factory technicians. Each hoist receives final inspection by quality managers before the equipment is packaged and shipped. These tests and inspections assure the installer and the owner that they are in possession of equipment that is not only safe and reliable but which will do the job from the first moment of use.

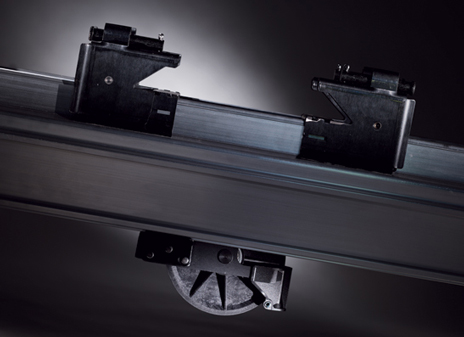

Prodigy Progressive Hybrid Sloped Drum

Drum design dramatically reduces the space needed for a motorized winch. Small drum size also means a streamlined Powerhead for the most compact and manageable rigging system on the market.

Prodigy Compression Tube

Rigging anywhere. The smart backbone of the Prodigy system absorbs and disperses lateral loads on building steel. Simply lift and snap into Mounting Brackets for lab-saving installation.

Prodigy Mounting Brackets

Smart ‘snap-in’ design for significant savings in installation time and labor.

Prodigy Cable Management System

Smart and safer. Saves valuable space above the ceiling by retracting compactly and storing in only 30″ of height. Keep the best of your existing system; add the best of the new.

Controllers:

The brains of the ETC rigging system…move and monitor battens with their simple, inexpensive or full-featured control systems.

QuickTouch + Controllers

Affordable, user-friendly controls for combination fixed- and variable-speed motors.

The QuickTouch+ control system allows for the control of mixed variable- and fixed-speed hoists. With the speed-adjustment slider, it is possible to set up a specific speed for the next move, or adjust the speed during motion. With five user-recordable positions in combination with speed control, you can easily use this controller to run predictable and repeatable show transitions.

The LCD screen displays real time data from the hoists and also displays diagnostics, so you know your system’s exact status at any given moment. The QuickTouch+ system also keeps track of its annual inspection schedule and records the usage of each motor (distance traveled, peak load and fault conditions since installation and last inspection). The easy-to-use commissioning-software package automatically produces a system inspection report in PDF format.

- Configurations available for controlling up to four, eight, 12, and 24 variable- and fixed-speed motors

- Accurate speed preset and live control via slider

- Three user-programmable trims and two user-programmable travel limits per motor

- Illuminated control buttons with dimmable backlight

- Status, position and load readout via LCD screen

- Hardwired E-Stop circuit and dead-man switch

- Hold-to-run controls

- Multiple languages available

- Imperial or metric readout information

- Automatic self-test at startup and after 30 days of continuous ‘on’ time

- Simple and cost-effective installation using standard CAT5e wiring

- Conforms to all CE directives and standards

Foundation HD Rigging Controller

Fixed- and variable-speed control of Prodigy hoists.

The powerful Foundation® HD controller allows you to easily create and run pre-programmed shows at the touch of a button. For multipurpose stages, presets can be used to create and restore specific stage configurations for recurring events, like movie nights, speeches, or band rehearsals. Stage technicians used to working with other controllers — such as lighting consoles — will find Foundation’s user interface familiar and accessible.

Each Foundation controller logs the use of the entire hoisting system and the behaviors of each motor, while also providing diagnostics on itself and the entire hoisting system. If a fault occurs, the motors communicate the type and location of the fault via the Foundation controller’s 18″ LCD screen. Foundation also tracks the system’s annual inspection schedule, and records the usage of each motor (moving distance, peak loads and fault conditions since installation and last inspection). The built-in inspection and commissioning software package automatically produces an inspection report in pdf format.

- Controls up to 48 or 96 variable- and fixed-speed motors

- Foundation server configurations with up to 192 axis and SIL-3 safety features

- High-resolution, full-color, multi-touch screen

- Proximity and ambient light sensor automatically controls LCD backlight to keep light pollution on stage to a minimum

- Status, position and load readout on screen

- Lockable user-control area with illuminated controls

- Proportional joystick for precise variable-speed control

- ‘Go’ button for movement execution

- Quiet, maintenance-free operation

- Optional external emergency-stop (E-Stop) stations

- Optional remote control

- Optional ‘Remote Cue Enable’ button: A spotter can enable a cue for execution

- Optional Foundation Handheld Remote

- Motor load-profiling: Stops movement at unexpected load conditions

- Automatic self-tests of all safety circuits

- Motor-usage data statistics and service-interval reminders

- Multiple languages (including English, Spanish, French and Russian)

- Metric or imperial data display

- Conforms to CE directives and standards